Launching your drilling production and profit light years ahead means mobilising a modern-day machine capable of swiftly sliding from rotary to automatic drop hammer, even to CPT or direct push, without having to reposition mast or machine. Success stems from geotechnical drill rigs and tooling designed to simplify traditional geotechnical techniques and add versatility to expand service lines.

Enginereed efficiency

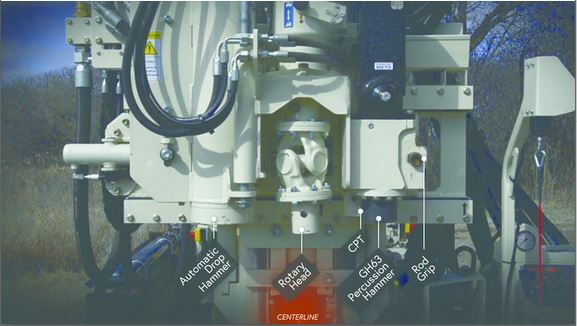

Multi-application or combination rigs like the Geoprobe® 3126GT geotechnical drill rig position companies for increased productivity and rig utilisation, offering:

• Centerline head side shift to trim time between applications by aligning all head functions and winches over the borehole without moving mast or machine

• Power and performance to effectively compete in multiple revenue streams - HSA, SPT, CPT, DPT, rock coring, mud rotary, air rotary, and drive and wash

• Simple controls with hands-free rotation, head feed, and auto drop hammer to make work nearly effortless and create a gentle learning curve for the seasoned driller as well as the new hire

• Separate hydraulic circuit dedicated to the mud pump to create stable mud flow by eliminating the battle between drilling functions and fluid circulation for hydraulic flow and pressure

While geotechnical site investigation methods vary greatly depending on regulations, subsurface formations, and acceptable practices in the region, what unites the industry is the need to complete the job easily, quickly, and most importantly safely.

Expanded safety

Safety features should go beyond just having E-stops, rotation guards, safety interlocks, etc. For example, Geoprobe® engineers also focus on how the operator uses the rig, such as:

• well-designed control panels with tactile feel controls grouped by function

• electric controls for hands-free operation

• adjustable positioning to reduce "drillers neck"

• passenger-side positioning to increase safety for the operator

Additionally, telescoping winch masts reduce the potential for drillers to collide with utility lines when deploying the drill, reducing the number of incidents. Options like mobile tooling drop racks capable of being positioned on-site for efficient access reduce fatigue, which in turn reduces injury.

Elevated cost savings

Selecting a single, versatile drilling rig that works well in a wide geographic area to easily and quickly complete an array of jobs can benefit the bottom line in a multitude of ways. Combination or multifunctional machines maximise efficiency of multiple resources - from personnel to capital - by:

• reducing maintenance costs over upkeep on multiple machines

• minimising mobilisation costs versus deploying a second - or even third - rig

• improving operational fuel efficiency with hydraulic load-sensing systems which provide power only when necessary and reduce the load on cooling systems

Enhanced tooling

Constant pressure to become more cost-efficient influences not only drill rig decisions but also tooling choices. With Geoprobe® drill rigs and tools designed, built, and supported as one, the end result is a highly-refined system that achieves reliable, consistent project results. Recent Geoprobe® geotechnical tooling innovations add noticeable ease and value.

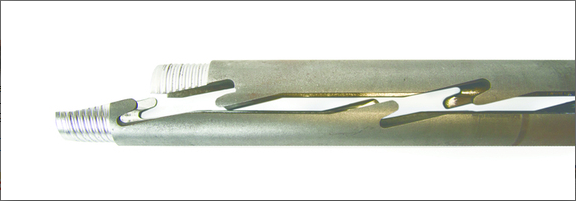

Interlocking Split Spoon Sampler

No more gripping split spoons with bench vises or beating them with wrenches. The Geoprobe® patented* interlocking design strengthens the entire sheath while also maintaining alignment during impact, eliminating bulging and bowing. Enhanced interlocking split spoon sampler material properties result in greater strength and longevity. Multi-lead threads require fewer turns when assembling for faster field operations.

Spring-assisted swivel lift cap

No more burning forearms from long days of twisting tool strings. Bearing the weight of the rod string, the Geoprobe® spring-assisted swivel lift cap makes removing drill rods from the tool string faster and safer. Springs in the cap control the winch line tension by counteracting the weight of the rods. The naturally self-aligning rod string requires less effort to make and break joints, reducing fatigue and increasing field performance.

End result

Rather than relying on the relics you're used to, modern-day geotechnical drill rigs and tooling offer effective, efficient alternatives to propel your geotechnical business forward. At Geoprobe®, driller feedback fuels innovation of rigs and tools designed for the user rather than just following the blueprint from the beginning of time while still meeting ASTM or AASHTO standards. Drillers around the globe have come to rely on Geoprobe® for a better, trusted product to complete faster, easier, safer drilling.

ABOUT THIS COMPANY

Geoprobe

Geoprobe® manufactures rigs and tooling engineered for efficiency, empowering companies to lead their industry.

HEAD OFFICE:

- Geoprobe Systems®, 1835 Wall Street, Salina,

Kansas -67401, United States - Phone: 785-825-1842

- Web: www.geoprobe.com

- Email: info@geoprobe.com