Whether traffic relief in urban centres, efficient cross-regional rail connections, sustainable energy supply or efficient water and sewage systems – the future of efficient and sustainable infrastructure lies underground and makes a decisive contribution to overcoming global challenges.

Projects such as the Grand Paris Express and the Mass Rapid Transit (MRT) in Singapore are bringing millions of people in the world's metropolises closer together. They create efficient, reliable transport arteries that make everyday life easier and promote economic development.

At the same time, megaprojects in the Alps are overcoming gigantic geographical obstacles. The transalpine routes, including the Gotthard tunnel and the Brenner and Mont Cenis base tunnels between Lyon and Turin (TELT), significantly reduce journey times and make freight and passenger transport more efficient and environmentally friendly.

But infrastructure is not just about mobility – the energy supply of the future also lies deep underground. Geothermal drilling is tapping into untapped potential for sustainable heat and power generation.

YOU MIGHT ALSO LIKE

Underground infrastructure is crucial for future-proof traffic development as well as for efficient supply and disposal networks. As the world's leading full-range supplier, Herrenknecht AG develops and supplies mechanised tunnelling technology that has been driving successful tunnelling projects for nearly 50 years.

At bauma 2025, Herrenknecht will present, under the motto "Exploring the green", pioneering solutions and comprehensive services that pave the tunnelling industry's path to greater sustainability and efficiency.

At bauma 2025, on an exhibition space of over 800sq.m, Herrenknecht AG will present the latest developments in mechanised tunnelling technology, together with references showcasing application examples worldwide. Five key thematic areas of the presentation (Hall C3, Booths 447 and 547) will focus on forward-looking trends such as digitalisation, automation in tunnelling and solutions for the sustainable use of resources.

Additionally, Herrenknecht Group specialists will present their solutions for the upstream and downstream processes of tunnel jobsites – from robot-supported segment production, smart transport vehicles, and precise navigation systems to efficient muck management.

Exploring the green

More sustainable use of resources is a cornerstone for the future viability of mechanised tunnelling, as is continuing to increase efficiency and occupational safety. Due to the diverse and complex challenges of underground construction projects, this requires solutions with equally many facets and dimensions: from a multitude of detailed solutions – such as the automated directional control of the gantries' carriages – to a comprehensive engineering guideline, according to which, for example, the later resource-saving rebuilding of components is planned in advance in the early phase of construction. The characteristic green of the Herrenknecht brand unites a team of experienced specialists with a globally unique portfolio of expertise and the offer to develop a customised solution for every customer requirement.

The motto "Exploring the green" of the Herrenknecht presentation at bauma invites visitors, customers and partners to explore the multifaceted solutions in five thematic areas and meet the experts personally.

Utility trends

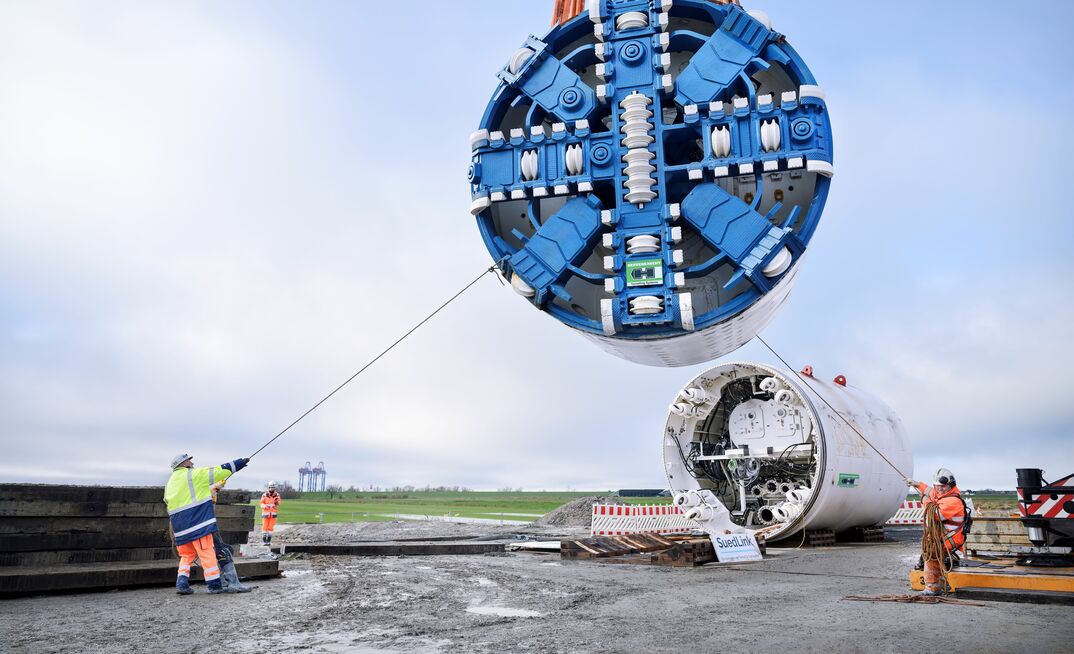

Urbanisation, climate change, and energy transition are placing growing demands on the expansion of underground supply and disposal infrastructure. Herrenknecht is meeting these demands with advanced technologies. An outstanding example is the ElbX project, a crossing under the Elbe for the Südlink Network Code on High Voltage Direct Current line (HVDC).

A Mixshield configured specifically for the project is being used, which was designed for the expected heterogeneous subsoil, high water permeability and the water pressure under the Elbe.

The Herrenknecht product range also offers solutions for crossings using horizontal directional drilling, for sewage systems or for seawater desalination plants.

Technological progress

Herrenknecht is a driver in the development of automation solutions that make mechanised tunnelling safer and more efficient. At bauma, Herrenknecht will be presenting advances in, for example, the automation of segment handling, ring building and the directional control of the tunnel boring machine.

In the High Speed Two (HS2) project, Herrenknecht is setting new standards in terms of safety and digitalisation with 12 state-of-the-art machines and advanced automation solutions. Together with Bouygues Travaux Publics, Herrenknecht developed the (semi-) continuous advance method used at HS2.

Green tunnelling

Herrenknecht pursues a holistic approach to more sustainable tunnelling with a focus on energy efficiency and resource conservation – always tailored to the individual requirements of customers and their projects. Targeted technological developments significantly reduce energy consumption, the use of lubricants and water requirements, for example, and thus the ecological footprint of the entire project. The reuse of professionally rebuilt components or machines reduces CO2 emissions by up to 95%.

Service experts

On 300 simultaneously supported jobsites worldwide, experienced Herrenknecht service experts ensure that machines and systems always work reliably: spare and wear parts, remote support with real-time troubleshooting, and tailor-made installation packages for a successful launch or practical and customer-specific training. Contractors can supplement their team with Herrenknecht personnel in a targeted and project-specific manner to ensure rapid tunnelling.

Digital insights

Herrenknecht is driving the digital transformation in tunnelling with innovative software solutions. The customer portal Herrenknecht.Connected enables seamless integration of data and processes, improves transparency and increases the efficiency of tunnelling projects in real-time. The digital transformation opens up new opportunities for collaboration, in-depth data analysis and profitable project management.

Mining

In mining, mechanised solutions are increasingly being used to create underground infrastructure. With a broad product range and a growing number of global references, Herrenknecht is continuously expanding its market position.

bauma Innovation Award

With the Tunnel Enlargement System (TES), Herrenknecht AG is a finalist in the Machine Technology category of the bauma Innovation Award. For the first time, the TES, developed by Herrenknecht together with contractor PORR, makes it possible to renew the lining of a tunnel during ongoing rail operations and bring it up to the current state-of-the-art or increase the diameter.

Herrenknecht is bringing its visions to life at the world's leading trade fair for construction machinery. Visitors to the booth can expect not only multimedia presentations and live demonstrations but also exclusive insights into current projects and the opportunity to exchange ideas with experts on the latest developments in tunnelling. Herrenknecht invites customers and partners to explore new directions for sustainable tunnelling together.