A UK National Highways project will be the latest to benefit from the supply and installation of the world's greenest ‘Green Steel', helping to generate significant carbon savings.

The £679 million upgrade of the A428 between Black Cat and Caxton Gibbet, with which Sheet Piling (UK) Ltd is involved on behalf of Skanska, is one set to transform one of the busiest road links in the East of England.

With new highways, junctions and bridges all needing to be constructed, this major project has many different elements. Some require temporary sheet pile works, all of which can benefit from the use of used sheet piles, with around 1000Te being installed in total.

By utilising used sheet piles drawn from Sheet Piling UK's extensive UK-held stock for this purpose, there is an instant carbon benefit to be derived. These temporary works piles will be installed at eight different locations over the course of 18 months.

YOU MIGHT ALSO LIKE

Once works are complete, extraction will take place, making the steel sheet piles ready for re-use once more, to derive every ounce of benefit from the carbon that went into their production.

Green steel and embodied carbon reduction

Lowering the carbon footprint of the project has also been taking place in another way. New bridge abutments at Roxton Road Bridge have been constructed using 14.5m-long Emirates Steel EZ38-700 Grade S430 GP steel sheet piles. In total, 50 crimped pairs of EZ38-700 sheet piles were installed to the north and south abutments. All sheet piles are supplied by Sheet Piling UK as green steel and come with the ultra-low embodied carbon value of 350kg per tonne of steel product.

This the greenest steel available within the industry

It is standard for Sheet Piling UK to supply projects with this super-green steel, regardless of project size. It is accompanied by independent certification from DNV, to allow contractors to have confidence in the validity of their embodied carbon reduction reporting.

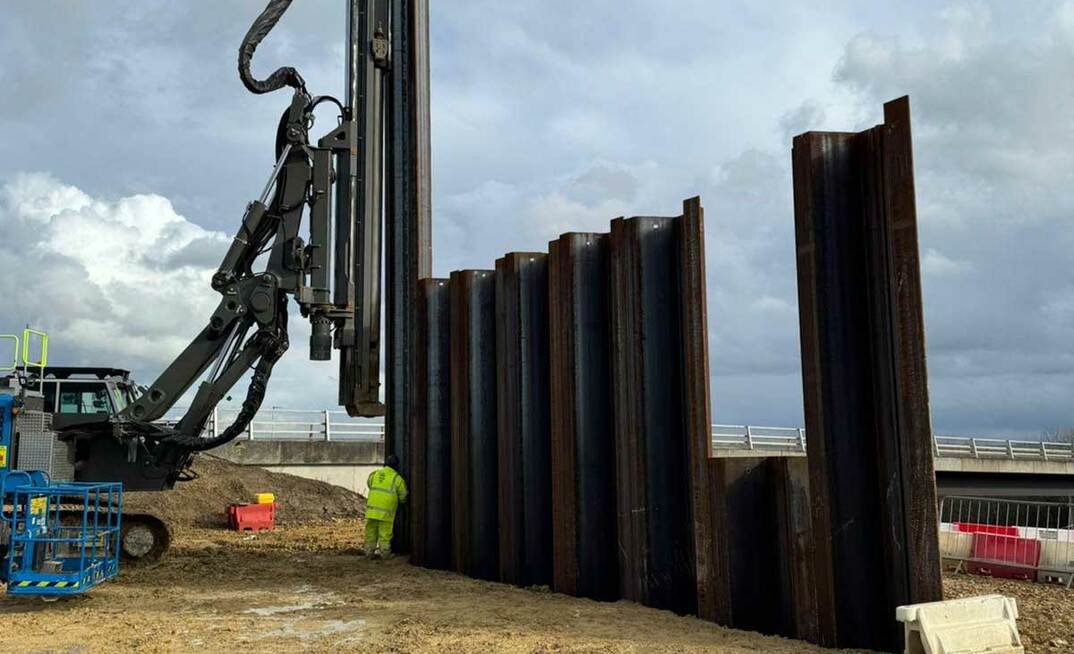

On this project, the sheet pile installation for the ST02 road bridge was swiftly completed over two weeks in March 2024. The installation was handled by Sheet Piling UK's unique ABI TM 20 long reach rig, fitted with MRZV30 vibratory hammer. This was serviced by another piece of plant from Sheet Piling UK's own fleet – a Sennebogen 50Te telescopic crawler crane. Pre-auguring of the pile line was necessary, due to the stiff clays on site.

Sheet Piling UK's advantages

"With extensive stock holdings for the supply of sheet piles, both used and new, a comprehensive fleet of plant, first-class, in-house design services and extensive installation expertise, Sheet Piling UK provides a one-stop service for contractors and other clients," managing director, Andrew Cotton, said. "This is clearly being evidenced on this highways project. Add to this the greenest steel available within the industry and we have a compelling offer to back our status as the UK's leading sheet pile supply and installation specialist."