Subsoil is an important resource for the heat transition as waste heat from industry can be stored there in the summer and used to heat residential buildings in the winter. The development of underground heat storage facilities sometimes requires innovative drilling technology. By using the innovative drilling method "Micro Turbine Drilling – MTD", Fraunhofer IEG was able to successfully create pathways for water in rock layers up to 500m deep. The drilling activity was part of an ongoing development under the Swiss capital Bern, which is to be expanded into a heat storage facility in future project phases.

By creating the necessary flow paths in the storage rock, we help to operate heat storage effectively.

"Heat storage is an important component of the heat transition," explained Niklas Geissler from Fraunhofer IEG, who, together with his team, developed the MTD process - drilling using a micro-drilling turbine. The turbine can be used from conventional boreholes to drill radial branches. This increases the inner surface of the borehole system in a controlled and reliable manner and increases the permeability for the working medium, water. "We are very proud to be able to use our process to help innovative projects such as that of the Bern public utilities to be successful. By creating the necessary flow paths in the storage rock, we help to operate heat storage effectively."

YOU MIGHT ALSO LIKE

Store heat for the winter

The regional energy supplier Energie Wasser Bern (ewb) is developing the "GeoSpeicher" (GeoStorage) pilot project at its Forsthaus energy centre. It is intended to store excess heat and use it during the winter months. In the Forsthaus energy centre, ewb operates a waste incineration plant, a wood-fired power plant and a gas and steam combined cycle power plant. These plants generate electricity and heat. The heat produced is fed into the district heating network. In summer in particular, the heat from waste incineration cannot be fully used. In winter, however, this heat would be in great demand.

This is where the GeoStorage pilot project comes in. In summer, the storage rock at a depth of up to 500m is to be heated with excess waste heat from the energy plants. The sandstone in the subsoil would be heated with 90-degree hot water like a tiled stove. In the winter months, the energy stored in the rock could then be recovered using water as the working medium at around 60 degrees Celsius and fed into the district heating network - exactly when demand is high.

In this way, the energy supplier could create a seasonal energy reserve of 12 to 15 gigawatt hours of heat. The GeoStorage would further increase the efficiency of the Forsthaus energy centre, lower the need for raw materials and reduce greenhouse gas emissions.

Drilling provides important insights

Three main boreholes have now been drilled to a depth of 500m. At depth, the project has discovered the coveted sandstone in several layers that are 35m thick in total. The evaluation of the geological data and initial circulation tests have shown that the rock layers are more compact than hoped and the achievable circulation of water cannot provide the necessary heat input and output.

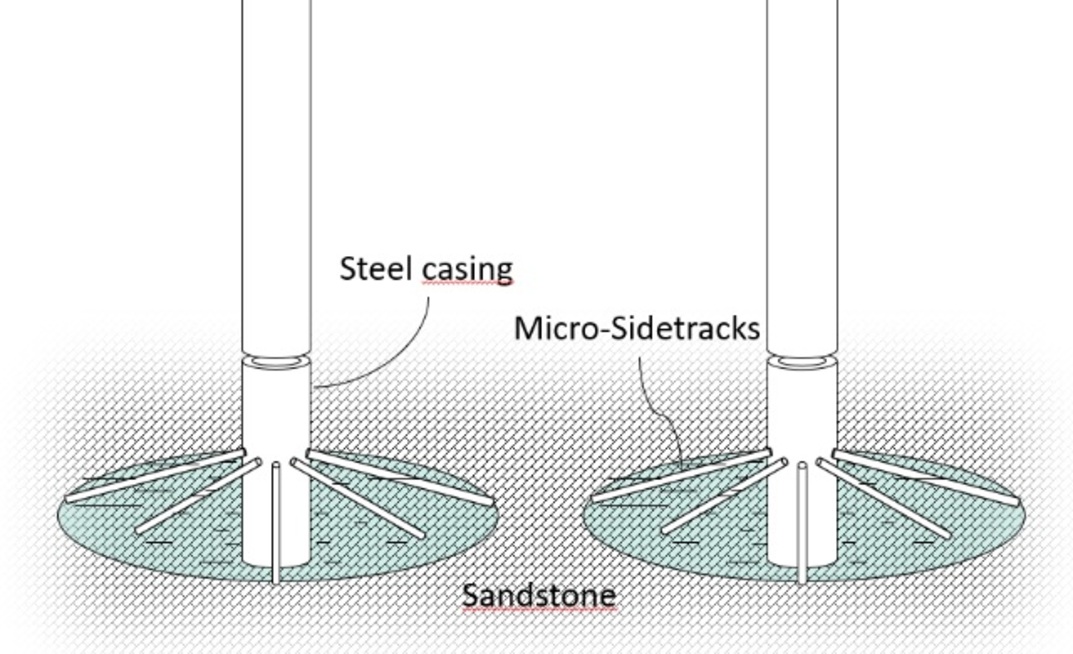

To improve circulation, the Fraunhofer IEG team has now drilled further avenues for the water using its new MTD technology. Micro Turbine Drilling - MTD uses a compact micro-drilling turbine equipped with a special drill bit. With dimensions of just 36mm in diameter and 50mm in length, the device is extremely small. The micro-drilling turbine is attached to a hose through which it is driven with up to 150L of water per minute at an inlet pressure of around 150 bar to set the bit in rotation. This consists of a tungsten carbide matrix with incorporated diamond grains and grinds at up to 80,000rpm, first through the steel casing of the borehole and then further into the rock.

The turbine can cover several metres per hour. The water that drives the microturbine also serves as a cooling agent so that the drill does not overheat, and also as a flushing agent to remove the drilling dust. In the GeoStorage project, the team from Fraunhofer IEG has now drilled more than 20 tributaries with an average length of 5m at a depth of around 500m. Energie Wasser Bern is now carrying out further hydraulic tests that will provide the necessary data for the next expansion phases.